Industrial growth in Dubai relies heavily on systems that allow equipment, materials, and tools to move efficiently across facilities. From logistics hubs to manufacturing plants and healthcare environments, mobility solutions quietly support daily operations. Among these solutions, Caster Wheels in Dubai play a foundational role in maintaining workflow continuity, safety, and spatial organization across industries.

Unlike fixed machinery, mobile equipment allows organizations to adapt quickly to changing operational demands. The ability to reposition loads without disruption improves efficiency and reduces strain on workers. This is where caster systems become more than mechanical components—they become part of operational design.

Industrial Mobility as an Operational Requirement

Movement is integral in industrial environments where things happen at higher speeds. Facilities are designed keeping in mind the regular relocation, adjustments, or reconfiguration of equipment. Caster Wheels are a common feature in carts, racks, workstations, and material handling platforms where this kind of flexibility is necessary.

Warehouses, for example, depend on predictable movement patterns to maintain safety and productivity. Straight-line transport, controlled turning, and load stability are all influenced by wheel design and material selection. Choosing the correct caster configuration ensures that equipment moves as intended without introducing unnecessary risks.

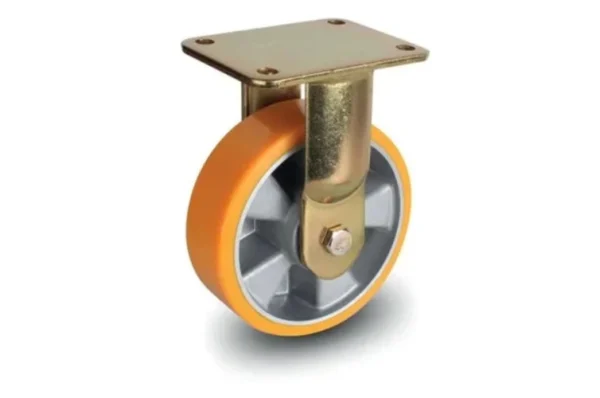

Load Handling and Structural Reliability

As industries expand, load requirements increase. Equipment is heavier, materials are bulkier, and operational cycles are longer. In such environments, mobility components must support not only weight but also repetition. Caster Wheels in Dubai are engineered to operate under continuous stress while maintaining consistent performance.

Structural reliability becomes especially important when equipment is moved frequently throughout the day. Wheel deformation, bearing failure, or uneven rolling can disrupt operations and increase maintenance demands. Selecting caster systems designed for industrial loads helps reduce downtime and prolong equipment life.

The Role of Stainless Steel in Demanding Environments

Certain industries require materials that can withstand harsh conditions without compromising hygiene or durability. Stainless steel caster wheels are commonly used in environments where moisture, chemicals, or frequent cleaning are part of daily operations. These wheels provide corrosion resistance and structural stability, making them ideal for use in food processing facilities, laboratories, and healthcare settings.

The benefit of these caster wheels is that they can maintain their performance without losing the material quality. In the case of cleanliness-controlled areas, the very critical factor would be the quality of cleaning the parts without any functional interference. The selection of this material is a guarantee of compliance and reliability in the long run.

Supporting Material Transport with Trolley Systems

Industrial and commercial facilities widely use trolley-based movement systems. Whether transporting tools, raw materials, or finished goods, trolleys must move smoothly while carrying significant weight. Heavy duty trolley wheels are designed specifically for these use cases, providing stability and controlled motion under load.

People often select these wheels based on floor conditions, load distribution, and frequency of movement. When properly matched to the application, reduce rolling resistance and minimize stress on both the wheel assembly and the surface beneath. This balance contributes to safer handling and more efficient workflows.

Floor Interaction and Wheel Selection

Different facilities present different flooring challenges. Smooth concrete, epoxy coatings, tiled surfaces, and outdoor pavements each require specific wheel characteristics. Caster Wheels in Dubai are selected with these variables in mind to ensure compatibility with local infrastructure and operational demands.

Wheel material influences noise levels, vibration, and floor wear. Softer materials absorb shock and protect surfaces, while harder compounds offer durability on rough terrain. Understanding how wheel properties interact with flooring helps facilities avoid unnecessary damage and improve overall movement quality.

Integrating Casters into System Design

Mobility solutions are most effective when considered as part of a broader system rather than standalone components. Equipment layout, load paths, and user interaction all influence caster performance. Facilities that integrate caster selection into early design stages often experience fewer operational issues over time.

This system-based approach ensures that components work together rather than against each other. The alignment of load ratings, wheel diameter, and mounting styles with real-life applications leads to the operation being less rough and the maintenance needs being lower.

Long-Term Performance and Maintenance Considerations

Industrial environments place continuous demands on mobility systems. Over time, wear is inevitable, but premature failure is not. Selecting high-quality caster assemblies reduces the frequency of replacement and lowers the total cost of ownership.

Regular inspection and appropriate material choices help maintain performance consistency. Stainless steel caster wheels, for instance, retain structural integrity in environments that would otherwise accelerate corrosion. Similarly, heavy duty trolley wheels are designed to withstand repeated loading cycles without compromising stability.

Industry Applications Across Dubai

Dubai’s diverse industrial landscape includes logistics, manufacturing, healthcare, hospitality, and construction sectors. Each relies on mobility solutions tailored to its operational needs. Various sectors in Dubai adapt caster wheels to support safe movement, optimize space, and enhance process efficiency.

From mobile storage systems in warehouses to transport carts in medical facilities, caster systems enable flexibility without sacrificing control. Their role may be subtle, but their impact is measurable in reduced handling time and improved workplace safety.

Informed Selection for Sustainable Operations

Choosing the right caster solution requires understanding both current needs and future demands. Load growth, environmental exposure, and usage frequency all influence long-term performance. Facilities that prioritize informed selection benefit from improved reliability and fewer operational disruptions.

Go Casters focuses on aligning caster components with real-world applications rather than isolated specifications. This practical perspective supports sustainable operations and ensures that mobility systems continue to perform as industries evolve.

Conclusion

Mobility is a key factor in contemporary industrial activities. Carefully choosing caster systems brings about efficiency, safety, and flexibility throughout the entire factory area. Caster Wheels in Dubai support this movement by enabling controlled transport under varying conditions. Combined with durable solutions like stainless steel caster wheels and heavy duty trolley wheels, they become a necessary part of the industrial infrastructure that ensures smooth and reliable operations.