Modern business environments and industrial workplaces require both mobile and stationary solutions to be successful. Heavy-duty braked rollers enable users to safely transport heavy, awkwardly shaped items through the workplace with enhanced stability and control. This reduces the risk of accidents. The team at Go Casters recognizes that businesses require high-performance heavy duty casters with brakes products tailored to their specific needs.

Selecting the right caster product can dramatically improve workplace safety and operational efficiency.

Why Heavy Duty Casters with Brakes Are Essential?

Moving heavy-duty equipment is difficult enough; securing it is even more difficult. Heavy-duty equipment can roll unexpectedly if the proper casters are not used. This creates a safety hazard for anyone near the equipment when it rolls away unexpectedly. Using heavy duty casters with brakes ensures the equipment is secure and safe. The brakes on these casters serve two functions: they act as wheels, and the brakes keep the equipment stationary while it is being operated.

Using a caster with a brake reduces workplace injuries caused by heavy-duty equipment. This protects the investments companies make in their heavy-duty machinery and enables them to place it accurately in its proper position.

Understanding the Key Features

These are the primary attributes when selecting robust casters with brakes:

Load Capacity: Heavy-duty casters are designed for heavy loads. Selecting an appropriate load capacity prevents overloading and resultant product failures.

Brake Mechanism: The brake may be on the side of the wheel, on the top of the wheel, or integrated into the wheel itself. Brake designs should securely hold the item without applying excessive force to the brake.

Wheel Material: Wheel materials include polyurethane, rubber, and metal. Depending on the application and the surface on which the casters will be used, each has its own advantages and disadvantages.

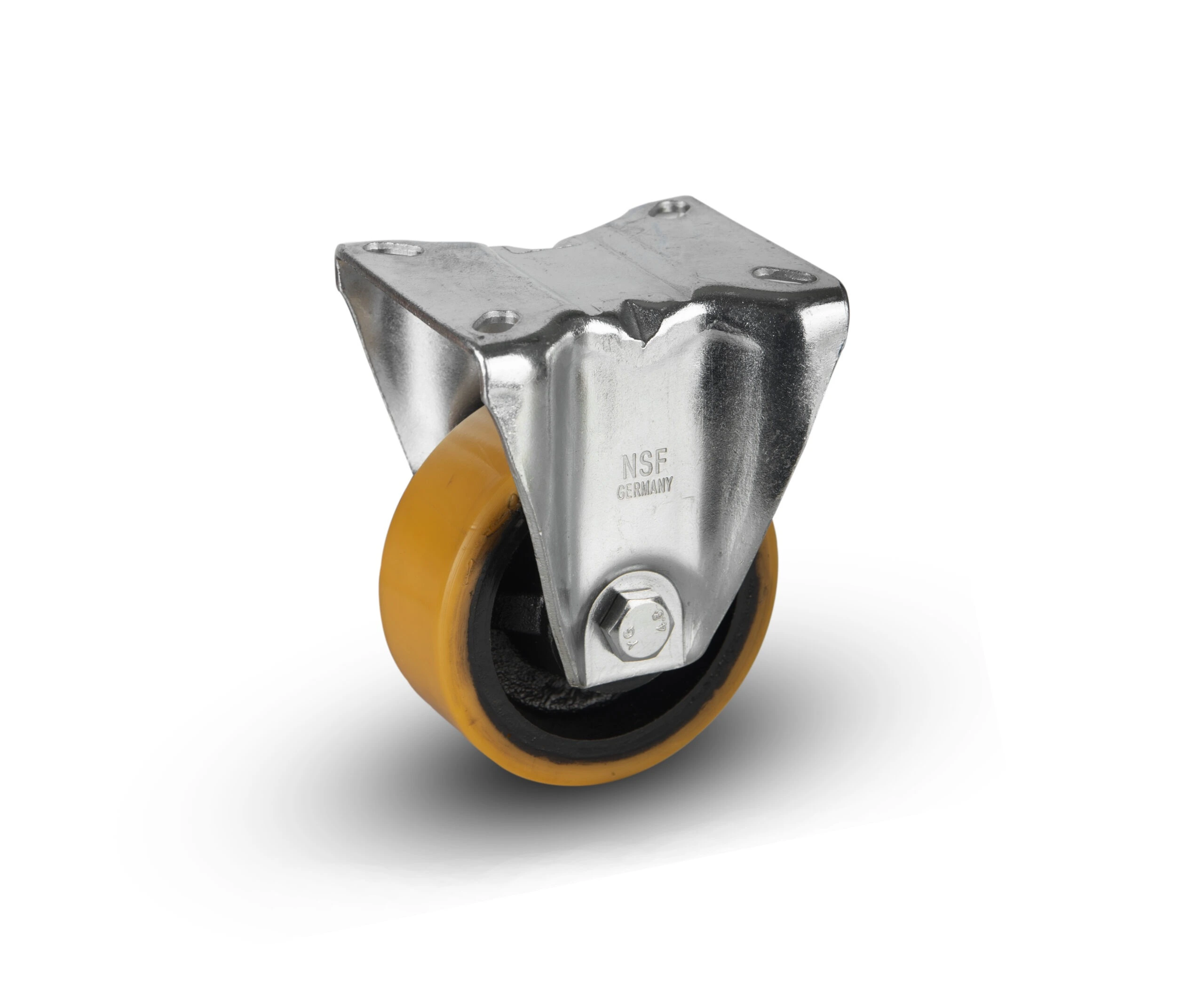

Swivel versus Rigid Caster: While swivel casters enhance maneuverability, rigid casters strengthen stability. Most applications use both types of casters to provide mobility and control.

By understanding the attributes above, organizations can select those that enhance operational efficiency and safety.

How Heavy Duty Casters with Brakes Improve Safety?

The safety benefits of heavy duty casters with brakes go beyond simple equipment stability. Here’s how they make a difference:

Accident Prevention: By locking equipment in place, brakes prevent uncontrolled rolling that can cause injuries or damage.

Operational Control: Brakes allow workers to stop and secure heavy machinery at precise locations.

Floor Protection: High-quality wheels reduce the risk of floor scratches or damage, which is crucial for maintaining workplace standards.

Efficiency: Workers can move equipment when needed and quickly lock it, minimizing downtime and enhancing productivity.

When businesses invest in heavy-duty casters, they invest in a safer, more controlled environment.

Applications of Heavy Duty Casters with Brakes

These casters are versatile and used in many industries, including:

Warehouses: Heavy-duty storage racks, trolleys, and platforms require secure mobility.

Manufacturing: Machinery and workstations often need to be moved for assembly line or maintenance purposes.

Medical Facilities: Hospital beds and medical equipment need smooth movement and secure positioning.

Retail and Display Units: Movable display racks benefit from brakes to prevent accidental rolling.

At Go Casters, our range of Caster Wheels Dubai serves diverse industries, providing reliable, safe solutions for businesses of all sizes.

Choosing the Right Caster for Your Needs

Selecting the right heavy-duty casters involves more than just picking a strong wheel. Consider these factors:

- Weight of Equipment: Ensure casters can handle the maximum load. Overloading can damage wheels and compromise brakes.

- Surface Type: Smooth floors may require harder wheels, while rough surfaces need shock-absorbing materials.

- Frequency of Movement: High-mobility setups need easy-to-swivel casters with reliable brakes.

- Environmental Conditions: Heat, chemicals, and moisture may affect wheel materials. Choose corrosion-resistant or industrial-grade wheels if necessary.

Understanding your operational needs ensures the right balance between mobility and control.

Case Study: Preventing Workplace Accidents

A warehouse client in Dubai experienced frequent minor accidents due to heavy trolleys moving unexpectedly during loading and unloading. They switched to heavy-duty casters from Go Casters, equipped with polyurethane wheels for floor protection.

After installation:

- Accidents dropped to zero within three months.

- Staff reported easier handling of heavy equipment.

- Productivity increased as trolleys could now be moved and locked efficiently.

This case highlights the importance of choosing high-quality, heavy duty wheels and casters to protect both employees and equipment.

Maintenance Tips for Heavy Duty Casters with Brakes

Even the best casters require regular maintenance to ensure performance and safety:

- Check Brake Function: Regularly test the brakes to ensure they lock and release smoothly.

- Lubricate Moving Parts: Swivel casters need lubrication to prevent stiffness.

- Inspect Wheels for Wear: Over time, wheel surfaces may develop cracks or flattening, reducing performance.

- Clean Regularly: Dirt and debris can reduce brake effectiveness and wheel mobility.

Routine maintenance extends the life of your casters and keeps equipment operating safely.

Customer Testimonials

“Our warehouse operations improved dramatically after installing heavy-duty casters from Go Casters. The equipment stays stable and moves effortlessly.”

— Logistics Manager, Dubai.

“The Caster Wheels we purchased handled our heavy storage racks perfectly. Brakes work reliably, ensuring safety for our staff.”

— Industrial Facility Owner.

“Switching to Go Casters’ heavy-duty casters was the best decision. We’ve reduced accidents, and employees feel safer handling equipment.”

— Operations Supervisor.

These testimonials demonstrate how quality casters improve workplace safety, control, and efficiency.

FAQs

Q1: Why should I choose casters with brakes over regular casters?

A: Brakes prevent equipment from rolling unexpectedly, improving safety and operational control.

Q2: Can heavy-duty casters be used outdoors?

A: Yes, but wheel material and brake design should match outdoor conditions, such as rough surfaces or exposure to moisture.

Q3: How often should I maintain my casters?

A: We recommend inspecting casters every 3-6 months, depending on usage, load, and environment.

Q4: What is the difference between swivel and rigid casters?

A: Swivel casters allow multidirectional movement, while rigid casters provide straight-line stability. Combining both offers a balance between control and maneuverability.

Q5: Can brakes handle maximum loads without failure?

A: High-quality heavy-duty casters are designed to hold the full rated load safely. Always choose casters based on the equipment’s weight.

Final Thoughts

Investing in heavy-duty casters is essential for any business that moves heavy equipment. These casters improve safety, provide operational control, and reduce workplace accidents.

By choosing high-quality, heavy-duty casters and working with trusted suppliers like Go Casters, businesses can enhance both efficiency and employee safety. Proper selection, installation, and maintenance ensure long-lasting performance and reliability.

Whether for warehouses, factories, hospitals, or retail spaces, Caster Wheels Dubai from Go Casters delivers mobility, control, and peace of mind. Protect your staff, secure your equipment, and invest in reliable casters today.